8 Key Applications of Light-Duty Cranes: Optimize Your Material Handling

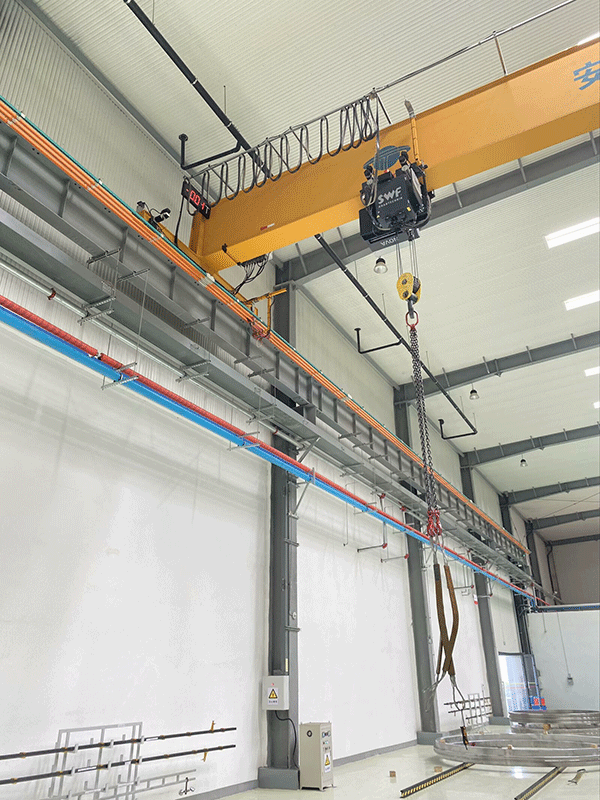

Light-duty cranes have become essential in lean manufacturing with their flexibility and cost-effectiveness. [Jiangyin Dingli High Tech Cranes Co.,Ltd.], a Chinese manufacturer specializing in European-style compact cranes, reveals their core applications and technical strengths.

1. Core Advantages of Lightweight Design

Plug-and-play: No foundation required, saves 90% setup time (4-8hrs vs 2-4 weeks for traditional cranes)

High mobility: 60% lighter than standard overhead cranes for easy workstation relocation

Precision control: 0.05m/min micro-speed mode for delicate instrument handling

2. 8 Prime Application Scenarios

1. Automotive Parts Assembly

Recommended: 500kg-2t jib cranes for 5-8m workstation coverage

Case: Boosted engine assembly efficiency by 40% for a Tesla Tier-2 supplier

2. E-commerce Warehousing

Solution: 1-3t electric hoist + I-beam rail system triples picking speed

3. Precision Machining Workshops

Tech feature: 200kg-1t aluminum rail cranes with anti-sway technology

4. Labs & Cleanrooms

Customization: Dust-free lubrication + 304 stainless steel (ISO Class 5 compliant)

5. Equipment Maintenance

Mobile solution: 500kg-5t portable gantry with 80% space-saving disassembly